Engineering Services

Experience of the full design and development process enables us to offer design and engineering services to fit in with any stage of a product's development lifecycle.

A few key skills and experiences are highlighted below. Please get in touch if you need any further information on what we can offer.

Key Skills

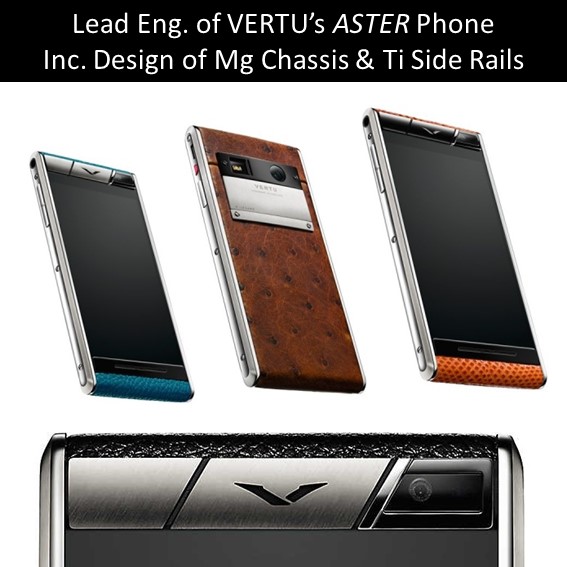

Concept Design, Solid & Surface Modeling

Freehand sketches and 3D-modelled design concepts. 15+yrs experience using Surface modelling and Solid modelling software. Experience of various modelling approaches: including top-down modelling with all data revision-controlled in PDM systems, through to the other extreme of managing revision control via folder structures alone.

Experience of handling PCB data as 'dumb' step imports, or collaborative working with electronics engineer's IDF/IDX and library data through add-ons such as Circuitworks.

Prototype Delivery

Experience of a vast range of 3D prototyping, and pe-production techniques, including handling of supply chain to deliver completed/working prototypes.

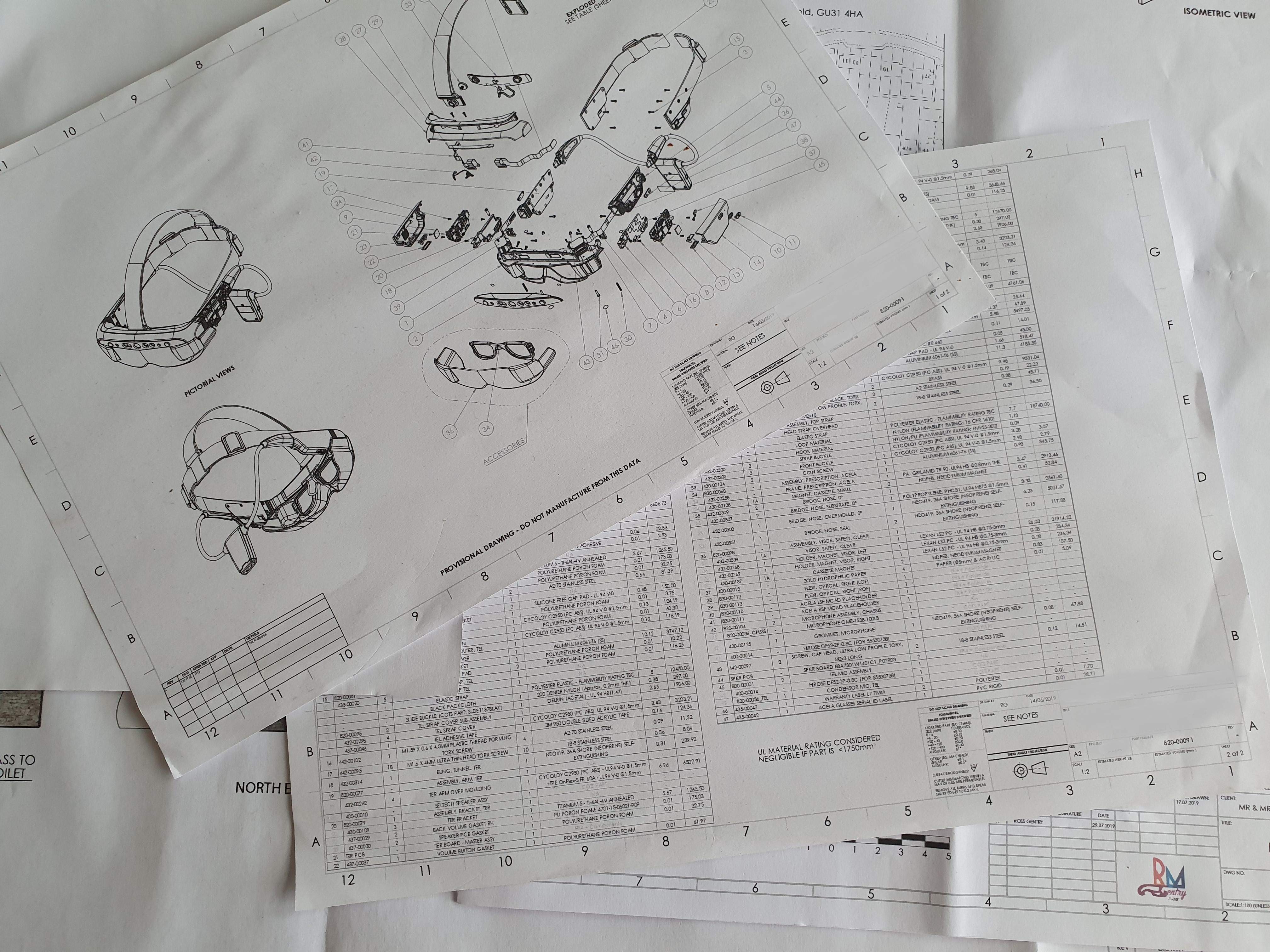

Detailed Design + Technical drawings

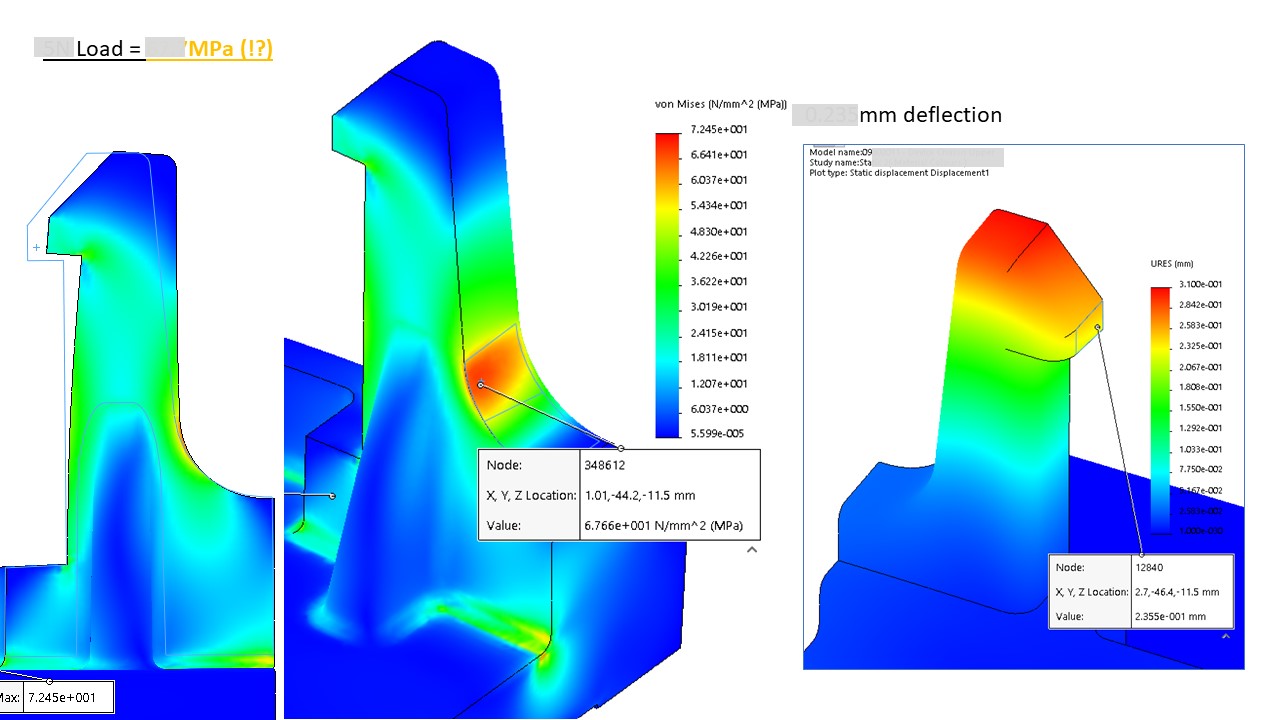

Clash/Clearance detecting assemblies, wall thickness analysis, basic component stress analysis, seal compressions, etc, etc...

Technical/production drawings (to BS8888), and an appreciation of the varying tolerances achievable for; injection mouldings, sheet metal, die-castings, forgings, CNC machining, various welded sub-assembly techniques, etc, etc...

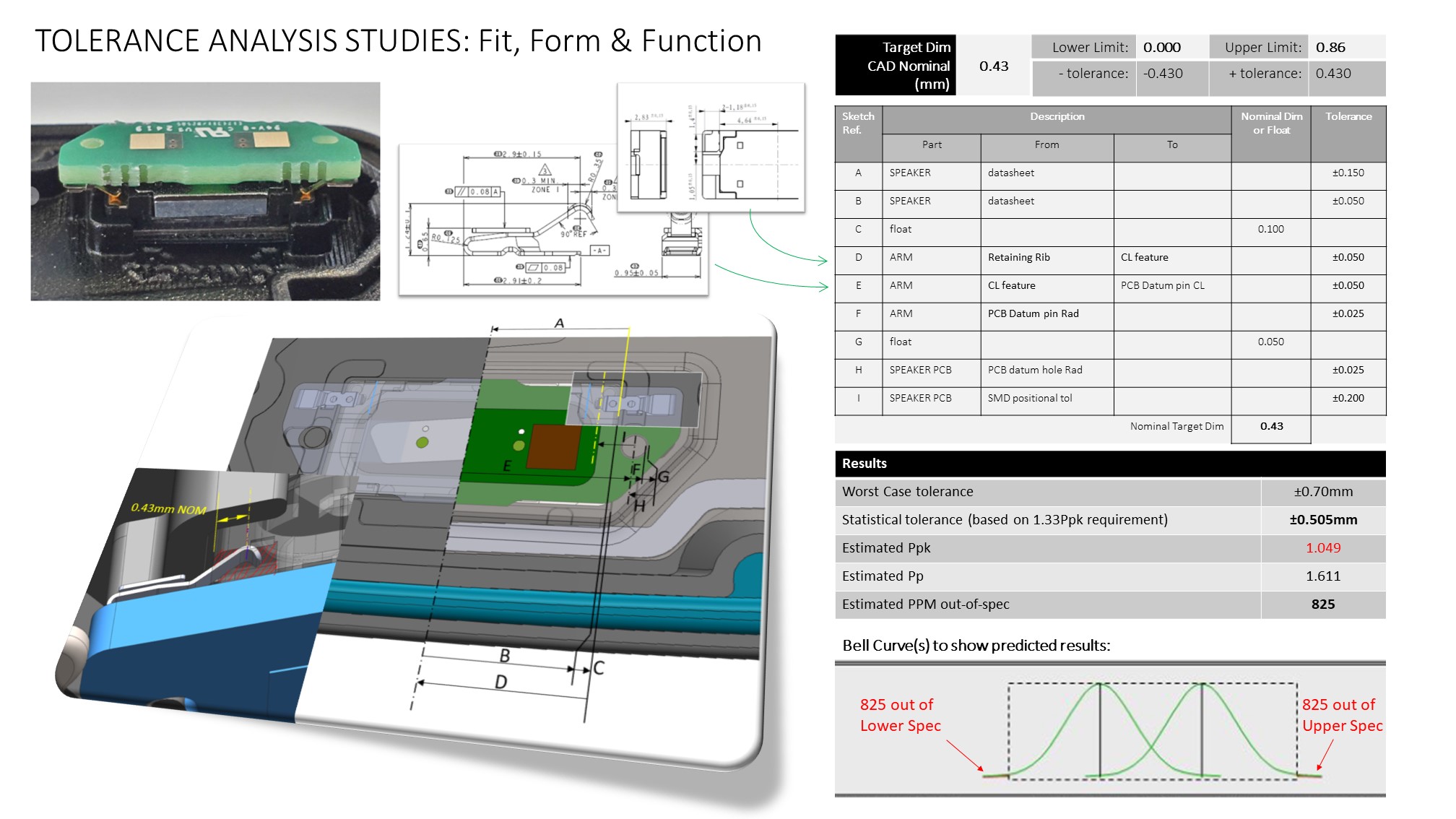

Tolerance Analysis & Design Reviews

Form, Fit and Function Analyses - Often a Key Part of Detailed Design, to check a design before any data release for tooling, but also done after a prototype release, when time-scales are tight, to sanity check a design.

Examples; Assembly (DFA) clearances, Predicting Cosmetic Gap variation, Switch activtion, Gasket/Seal compressions, DFMEAs (8D root cause Analysis if there are problems with existing designs/processes)...

CAD Software Experience;

- SolidWorks 2016-Present - own license and support

- Catia v5 2008-17

- Pro-E/Creo 2.0 2014-15

- UGS NX v4/v5

2007-08

- IDEAS v11 2004-07

+ Various PDM systems